14. May 2025 By Stephen Lorenzen

AI for efficient and fail-safe power plant maintenance

How data-driven maintenance secures energy supply

Power plants are the backbone of modern energy supply. An unexpected outage can have far-reaching consequences – from millions in lost revenue to disruption of critical infrastructure. Operators must ensure that their plants run reliably while being maintained in a cost-efficient manner.

A leading energy supplier was faced with precisely this challenge: How can failures be detected early and maintenance processes optimized without incurring unnecessary costs? To solve this problem, a data-based solution based on machine learning and generative AI was developed in collaboration with adesso.

The solution: a data-driven maintenance system with AI

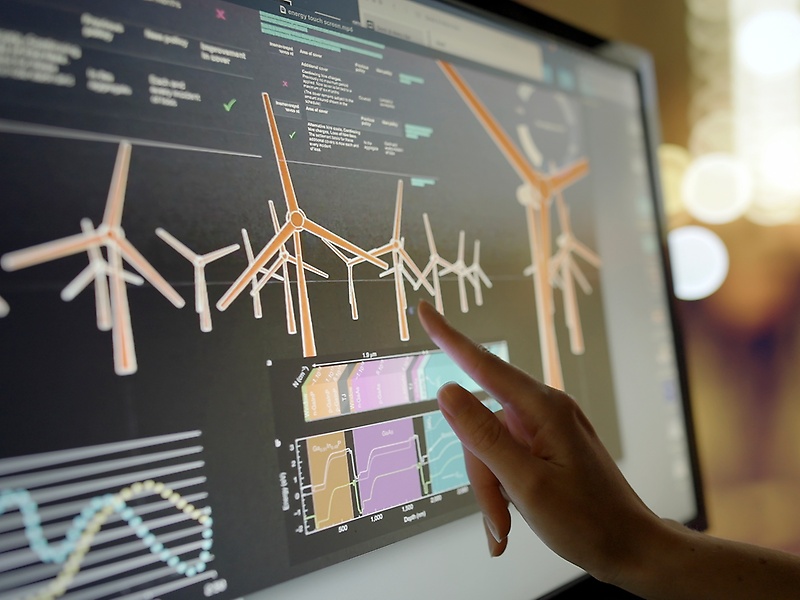

The central idea behind the new strategy is to develop a “single source of truth” dashboard that bundles all relevant factors influencing maintenance in a central platform. This solution is based on Microsoft Power BI and is fed by a proprietary data and digital platform that intelligently links data from various sources.

The key components of the solution

1. Predictive analytics for proactive maintenance

To avoid unplanned downtime, machine learning models are used to continuously monitor the condition of individual components. Three core metrics are calculated:

- Health Score Service: Displays the current condition of the components.

- Failure Probability Service: Estimates the probability of a failure.

- Failure Impact Service: Calculates the financial impact of a possible failure.

These models enable data-driven decision-making. Maintenance is no longer performed at fixed intervals, but only when it is really necessary – before a defect occurs.

2. Virtual assistant to support engineers

An integral part of the system is an AI-powered virtual assistant based on a large language model (LLM). This assistant helps engineers by:

- Searching maintenance documents and providing relevant information

- Answering questions about health scores and failure impacts

- Providing maintenance instructions

- Supplementing the dashboard with additional contextual information

As a result, engineers no longer have to search for information in different systems – they receive an informed answer in seconds.

Generative AI for the energy industry – innovation that makes an impact

From smart maintenance to intelligent customer communication: GenAI is helping energy suppliers tap into new potential for efficiency. Discover how adesso is driving your digital transformation with industry-specific expertise and powerful AI solutions.

3. Mobile applications for end-to-end documentation

Maintenance work is recorded directly on site in a mobile app and automatically synchronized with the dashboard. This ensures complete documentation and improves transparency regarding the measures carried out.

4. Integration of market data for economically optimized maintenance

A particular innovation is the linking of the system with current market data. This includes:

- Electricity prices

- forecasts for solar and wind energy, and

- local weather data.

This allows maintenance to be optimized not only technically, but also economically. For example, a power plant can be maintained when high feed-in rates from renewable energies reduce the demand for electricity from fossil fuel power plants.

Added value: increased efficiency and cost savings

The introduction of the new maintenance strategy has resulted in significant economic and operational benefits:

- Reduced downtime costs: A pilot project has already prevented losses of several million pounds.

- Greater reliability: Early detection of wear and corrosion reduces the risk of unplanned downtime.

- Optimized maintenance cycles: Precise calculation of the optimal maintenance time saves unnecessary repairs and extends the service life of components.

- Increased efficiency: Thermal output has been increased by approximately one percent – a saving in the millions.

Conclusion: Future-proof maintenance with AI

The introduction of a data-driven maintenance system has proven to be a real game changer. The combination of machine learning, generative AI, and an intuitive dashboard solution leads to a more sustainable, efficient, and economical maintenance strategy.

The energy supplier now plans to work with adesso to gradually roll out the system to up to 30 power plants. This will not only further increase operational reliability, but also make a decisive contribution to the digital transformation of the energy industry.

We support you!

With our experience in developing and implementing AI-based maintenance solutions, we offer you customized strategies for increasing efficiency and reducing costs. Find out how we can revolutionize your maintenance processes with data-driven analytics and innovative technologies.