Quality controls play a crucial role in automotive production. This is the only way to satisfy customers, fulfil legal requirements and ultimately achieve economic success. However, many production processes are based on outdated systems. These systems often run slowly and thereby impair operations management. A solution is urgently needed.

The future of quality assurance in the automotive industry

From manual coordination to centralised control

Replacing outdated systems and optimising quality controls

What is the current situation?

Cross-plant operations are often coordinated manually. This means that there is always a delay when tending to downstream processes. These processes usually have to be documented on paper, which makes it all more difficult. Tracking the status of follow-up work is time-consuming and prioritisation is done manually in an Excel file. When doing things this way, sustainable reporting and deep integration into production-relevant systems is not possible.

How can it be done better?

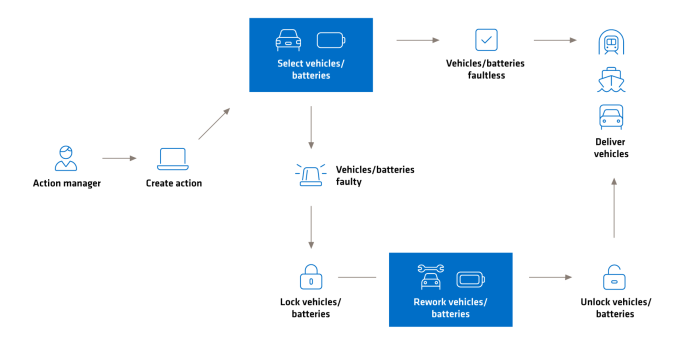

Modern IT systems make it possible to track the progress of repair work in real time and transparently prioritise vehicles. A central application that makes important applications available in one place is no longer a vision, but rather has long since become reality. It controls follow-up work, locks vehicles and components during production and thereby makes a decisive contribution to quality assurance. Seamlessly connecting external service providers while factoring in relevant security guidelines is also possible and saves time and effort in terms of management.

How does it work?

The technical approach

In addition to the higher degree of scalability and improved performance, moving to the cloud offers another advantage: the microservice architecture supports the decoupling of the production system. This allows the system to be centralised, which makes it possible to coordinate cross-plant operations and implement electronic feedback on the progress of follow-up work. This replaces the previous paper-based documentation and thus increases production efficiency.

A new centralised system for quality assurance in the motor vehicle production sector offers numerous advantages:

- Real-time tracking of progress on follow-up work

- Transparent vehicle prioritisation

- Highly efficient queries for identifying the number of affected vehicles

- Connection of external service providers while factoring in relevant security guidelines

- Management of cross-plant operations

- Scalable, modern software architecture

- Savings through digitalising paper-based documentation

With our cloud strategy your digital transformation takes off

Speed and time-to-market - these are the primary goals for the path to the cloud. This topic has also long since arrived in the automotive sector. Legal and security-related concerns have already been eliminated in recent years by the legislator or by a modified offer from cloud providers.

A suitable cloud strategy is required so that companies in the automotive industry can address this issue. We support you in this.

Do you have any questions?

There is no website or brochure which can replace a personal meeting to talk about your goals and topics. We are looking forward to an appointment on site.

Business Line Lead Sebastian Wessel +49 151 58334015 sebastian.wessel@adesso.de